Vertical V Groover Machine

General Features

Why Choose Durmapress

The horizontal part is machined with a rabett cutter 1/16" deep or deeper depending on the cove radius. This production method, even though more time consuming, will eliminate the hole in the corner altogether as well as the 45 degree bottom back bevel in the case of an open side view.

The vertical slotting machine adopts the precision ball screw as the power transmission component and has the characteristics of high processing precision, which is especially important for high performance products.

The machine has three-axis, X-axis (longitudinal moving of the tool tip), Y-axis (up and down), Z-axis (vertical moving of the tool tip) servo motor control, realizes full-automatic operation after parameter input, and comprehensively improves the planer Precision.

The pressing system uses the hydraulic system as the power, the pressure is large, and the fastening force is reliable. At the same time, low noise and low energy consumption.

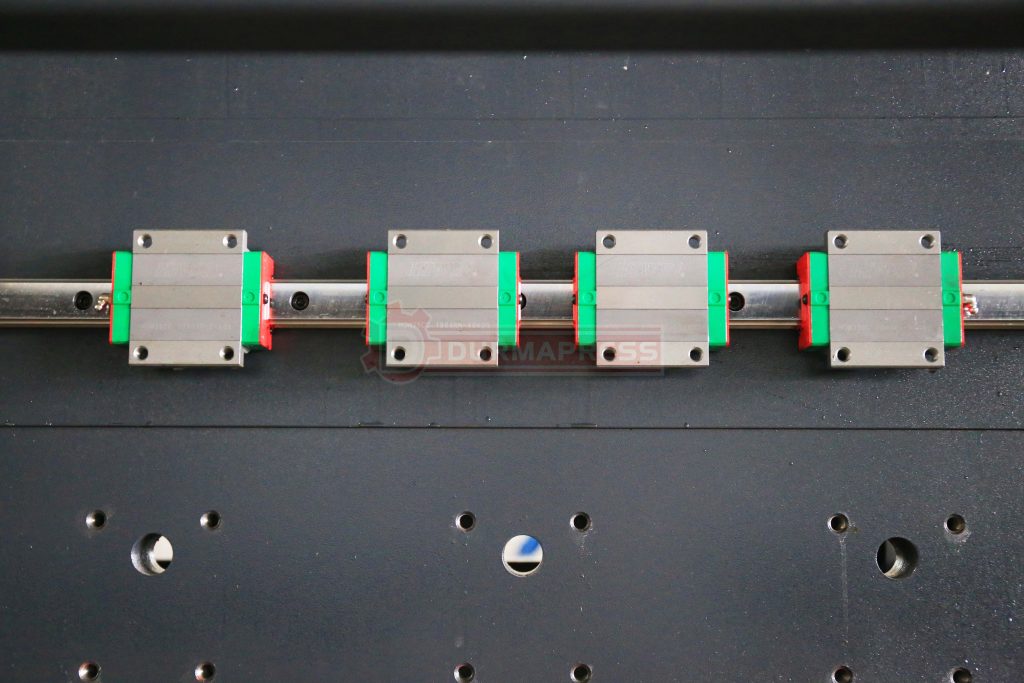

The rear moving part is driven by double ball screw, and the positioning accuracy of the board surface is high.

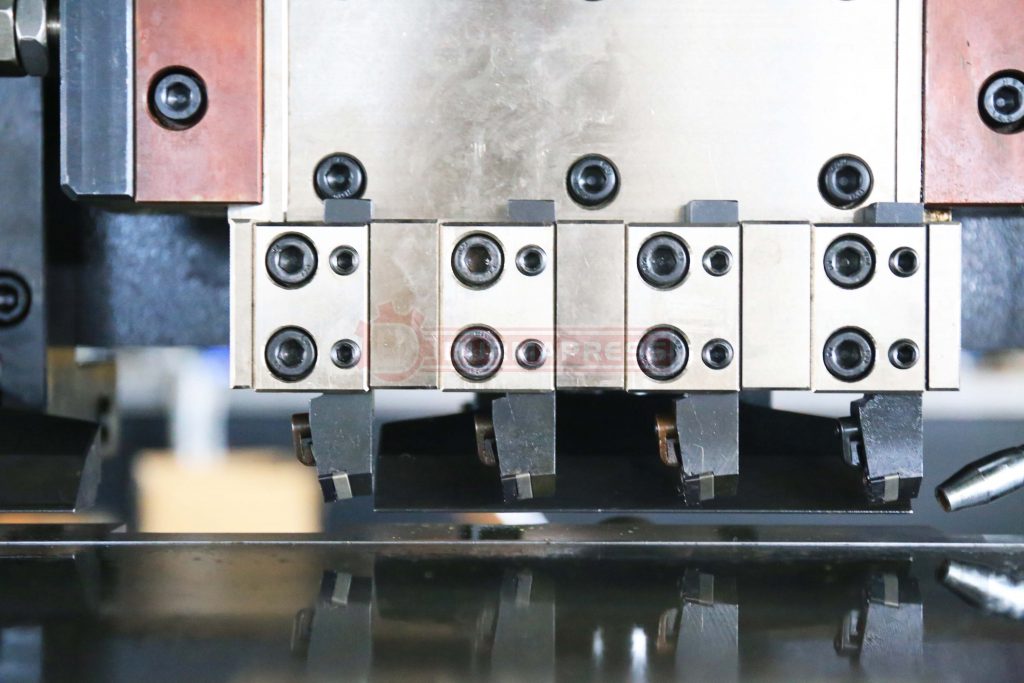

The tool holder slide is made of cast iron material, which is wear-resistant and repairable, and the service life is guaranteed for more than ten years.

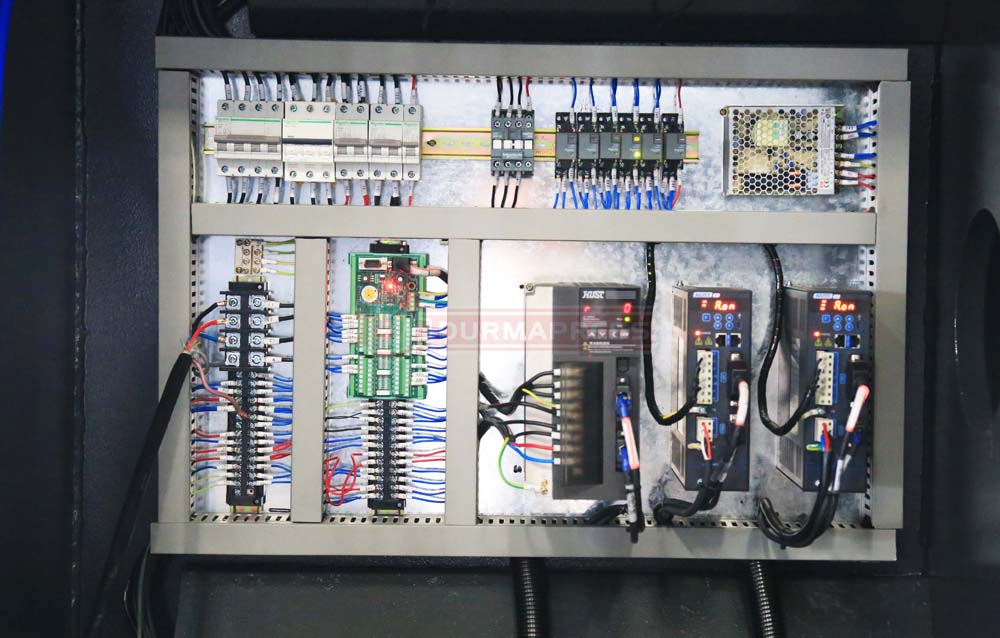

Components

Standard equipment:

- CNC system -Taiwan Hydraulic system - Taiwan

- Frequenc·y converter - Mitsubishi Servo motor - Mitsubishi

- Seal ring - VALQUA,Japan Motor - SEW

- Air switch - Schneider Contactor - Schneider

- Breaker and button - Schneider Relay - Schneider

- Blades - KORLOY,Korea

- Linear guide - HINWIN, Taiwan Wire - IGUS, Germany

- CE certified machine

Optional features:

- Blade with different material for cutting mild steel, brass, aluminum etc.

Main Components

Taiwan Hust Controller

- Shorten training time

- Avoid collision

- In any axial direction can be installed with grating ruler

- Responsive time for acceleration / deceleration : 0.5US

- High-speed positioning of main shaft

- With retraction function

- Intelective fault alarm and troubles shooting function

- PLC interrupt function : fixed scan time 10ms

- All axes open-loop control with feedback function

- The servo motor torque can be read and displayed

- The acceleration and deceleration control curve is

- superior to other numberical control .

- With DC power input module

- With SSR external unput singal plate

- Easy wiring , low wiring cost

4 Pieces Blade

- Three hundred whitesteel knives simultaneously cutting

Taiwan HIWIN Linear

- Taiwan HIWIN Linear Guide rail &

- Ball Screw

Light Protection

Front Photoelectric safety protection

Product Introduction Video

CNC V Groove Machine Working Video

V-Grooving, a method used to provide added aesthetic to a wide variety of applications, creates decorative patterns on the surface of products such as glass panels, picture frames, and wall cladding.

Primarily used to facilitate the bending or folding of various materials, V-Groove machining creates a V-shaped cut or channel along the surface of a material. This cut along the fold line acts as a hinge, allowing the product to achieve 90-degree bends with relatively small bending radii.

V-Grooving is often employed in many applications where traditional bending methods such as forced bending, free bending, and three-point bending are impractical.

Gallery

Technical Data

| No | Content | Required Parameter | |||

|---|---|---|---|---|---|

| 1 | Model | DMP1250-3200 | DMP1250-3200 | DMP1500-3200 | DMP1500-4000 |

| 2 | Plate thickness | 0.4-6mm | 0.4-6mm | 0.4-6mm | 0.4-6mm |

| 3 | Plate length X Width | 1250x3200mm | 1250x4000mm | 1500x3200mm | 1500x4000mm |

| 4 | Grooving speed | 5M-70M/min | 5M-70M/min | 5M-70M/min | 5M-70M/min |

| 5 | Feeding speed | 0.5-20M/min | 0.5-20M/min | 0.5-20M/min | 0.5-20M/min |

| 6 | Min-setting unit in X -axis | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

| 7 | Positioning precision in X-axis | ±o.o5mm | ±o.o5mm | ±o.o5mm | ±o.o5mm |

| 8 | Min-setting unit in Y -axis | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

| 9 | Positioning precision in Y-axis | ±o.o5mm | ±o.o5mm | ±o.o5mm | ±o.o5mm |

| 10 | Min-setting unit in Z-axis | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

| 11 | Positioning precision in Z-axis | ±o.o3mm | ±o.o3mm | ±o.o3mm | ±o.o3mm |

| 12 | X-axis motor power | 1.5KW | 1.5KW | 1.5KW | 1.5KW |

| 13 | Y-axis motor power | 3KW | 3KW | 3KW | 3KW |

| 14 | Z-axis motor power | 0.4KW | 0.4KW | 0.4KW | 0.4KW |

| 15 | Workbench planeness | ±o.o2mm | ±o.o2mm | ±o.o2mm | ±o.o2mm |

| 16 | Feeding Way | Back feeding | Back feeding | Back feeding | Back feeding |

| 17 | Workbench is replaceable or not | Replaceable | Replaceable | Replaceable | Replaceable |

| 18 | Workbench is quenched or not | Yes | Yes | Yes | Yes |

| 19 | Number of cutter | 3 PCS | 3 PCS | 3 PCS | 3 PCS |

| 20 | Max.Depth for one-time Grooving | 1.0mm | 1.0mm | 1.0mm | 1.0mm |

| 21 | Max. Grooving Depth | 3.0mm | 3.0mm | 3.0mm | 3.0mm |

| 22 | Cooling sprayer | Have | Have | Have | Have |

| 23 | Outline Diemension | 5000*2500*2100mm | 5800*2500*2100mm | 5000*2750*2100mm | 5800*2750*2100mm |

| 24 | Weight | 9500KGS | 10500KGS | 10200KGS | 11200KGS |