Laser tube cutting machines

General Features

BS6020T automatic Laser tube cutting machines (automatic fiber tube laser cutting machine, tube laser cutting machine) introduced German fiber laser cutting equipment solutions, equipped with FSCUT numerical control system. The frame adopts a welded structure, and the X axis is driven by a precision rack and pinion; the self-centering chuck is designed with stable structure, good rigidity, light weight, and high dynamic response. Provide customers with a fiber laser cutting system with high dynamics, high efficiency and low energy consumption to improve economic efficiency. It is a fully automatic laser tube cutting machine with excellent performance.

Why Choose BS6020T

1. The core transmission components and control system adopt German original parts, with high acceleration and stable dynamic performance.

2. The cutting head of this laser pipe cutting machine adopts German Precitec-HP series, high dynamic 2D constant focal length cutting, when cutting processing parts of different thickness, the replaceable box can quickly change the focal length. At the same time, because the mechanical interface is consistent with other HP series processing heads, CO2 or fiber laser can be used alternately quickly.

3. It can realize automatic feeding, aligning and measuring the pipe material, and realize efficient cutting.

4. The electric control box is equipped with an intelligent temperature control system to realize stable operation under various extreme climates such as high temperature and low temperature.

5. The intelligent dual-temperature control cold water system realizes independent control of the laser and optical system, and realizes stable operation in harsh environment and climate.

6. The Laser tube cutting machines adopts an automatic discharging system to recover the processed workpieces and slow down manual intervention.

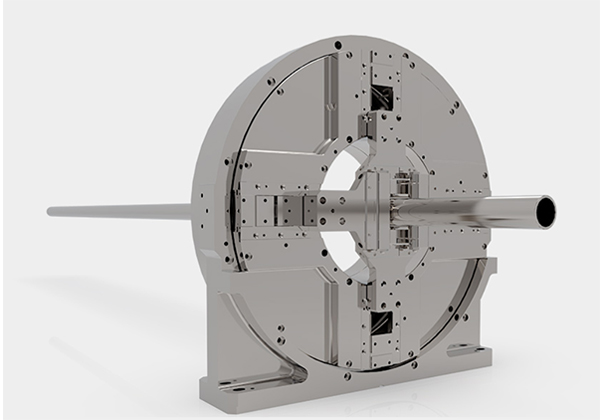

7. The laser pipe cutting machine adopts self-centering chuck design, light weight, high response dynamics, and air source rotating supply mode.

8. It can process and cut a variety of different pipe shapes, sizes and thicknesses.

9. YC-QG laser pipe cutting machine control system adopts FSCUT numerical control system, with adaptive look ahead function (Adaptive Look Ahead), which can preprocess 1000 NC program segments in real time. The "curvature optimization function" of the system can make a large number of continuous small line segments processing achieve excellent results, and better ensure the rapidity, continuity and stability of the processing process. Leapfrogging, retreat and high-speed electronic shutter functions can cut high-speed and high-precision.

Laser tube cutting machines cutting tube type

Round pipes, square pipes, rectangular pipes, D-shaped pipes, triangular pipes, elliptical pipes and other special-shaped pipe angle steel, channel steel and H-shaped steel

Cutting material: carbon steel, stainless steel, galvanized iron, alloy, copper, aluminum and other metals

The cutting system of the YC-QG series automatic laser pipe cutting machine can cut on any side of the pipe or along the length of the pipe. Different processing procedures are automatically completed at one time in one device. This system can cut square tubes, round tubes, rectangular tubes, oblate tubes and other metal materials such as stainless steel, carbon steel, aluminum alloy, titanium alloy, and bronze. Professional laser tube processing with less floor space, high degree of automation, faster processing efficiency, more flexible processing graphics, and lower processing costs

Optical fiber automatic focusing fiber cutting head NC30B

1. This cutting head has strong advantages in the application of medium-power large-format fiber laser cutting.

2. The internal structure of the laser head is completely sealed to prevent the optical part from being polluted by dust.

3. The laser head adopts two-point centering adjustment, and the focusing is driven by an imported motor, which is efficient in perforation

Significantly improved.

4. The protective lens is installed in a drawer type, which is easy to replace.

5. It can be equipped with various lasers with QBH connectors.

Laser Source

JPT single mode fiber laser(500W-2000W) is the optimal combination of optical, mechanical, electrical and software components. Through the controlling ports and the controlling software, the operating status of the laser can be monitored in real time, alarm messages can be received in time, and data can be collected. The laser uses water-cooling and shelf case design, with competitive advantage like high energy conversion (electric to light), low power consumption, maintenance free, fiber delivery, and easy to assemble, it is the most suitable laser source for industrial laser welding, cutting and other applications.

Yaskawa Reducer

Advantages:

High startability and short acceleration time; the reducer runs smoothly and has low noise;

Easy to install, save space and weight; reducer

Gears and racks can be adjusted to appropriate accuracy;

Good structure design, low moment of inertia;

The equipment can bear axial/radial thrust under heavy load;

The output shaft of the reducer is equipped with a set of high-strength rolling cone bearings;

Automatic Chuck

1. The characteristics of the electric chuck are: fast speed, high precision and long life.

2. Through the switch on the electric control box, the clamping and unclamping of the power chuck driven by the motor can be realized, and the forward and reverse rotation of the motor can be controlled. Adjust the voltage adjustment knob on the electric control box to adjust the drive voltage. Changing the output torque of the motor and adjusting the clamping force of the chuck make it more convenient to use.

OTHER COMPONENTS

-

- Automatic Lubrication System

-

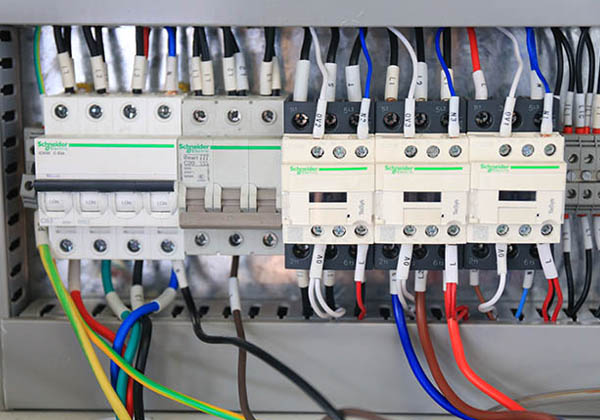

- Schneider Electrical

-

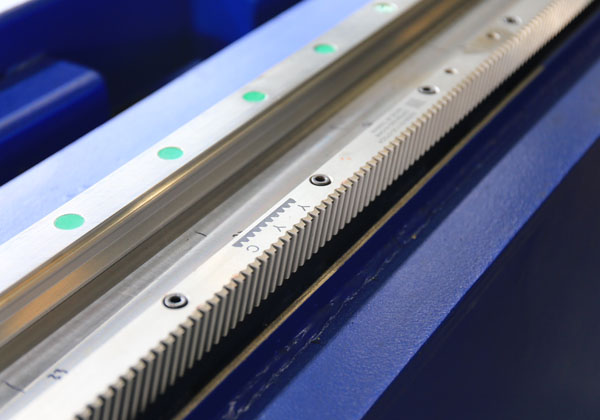

- YYC Gear

-

- Air Conditional

-

- Precite Cutter Head

-

- Yaskawa

-

- Water Chiller

-

- Topsinn Filter System

-

- Wireless Controller

| No | Technical Data | Remark | |

|---|---|---|---|

| 1 | Working Area(L*W) | 6500mm*Dia460mm | Round Tube/Square Tube |

| 2 | X axis distance | 6520mm | |

| 3 | Y axis distance | 350mm | |

| 4 | Z axis distance | 240mm | |

| 5 | X/Y axis position precision | ±0.03mm/m | |

| 6 | X/Y axis re-position precision | ±0.02mm | |

| 7 | X/Y axis Max. speed | 80m/min | |

| 8 | A、B axis travel / position precision | Infinite rotation/±0.03mm | |

| 9 | Pipe Diameter | Φ20mm-Φ460mm | Complete pneumatic chuck |

| 10 | Pipe Length | 300mm-6500mm | |

| 11 | Max. Loading Weight | 1500KG | |

| 12 | Dimension | 16900mm*4300mm*2400mm | |

| 13 | Weight | 9000KG | |