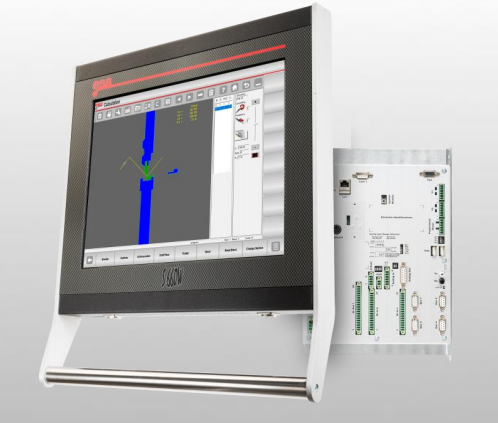

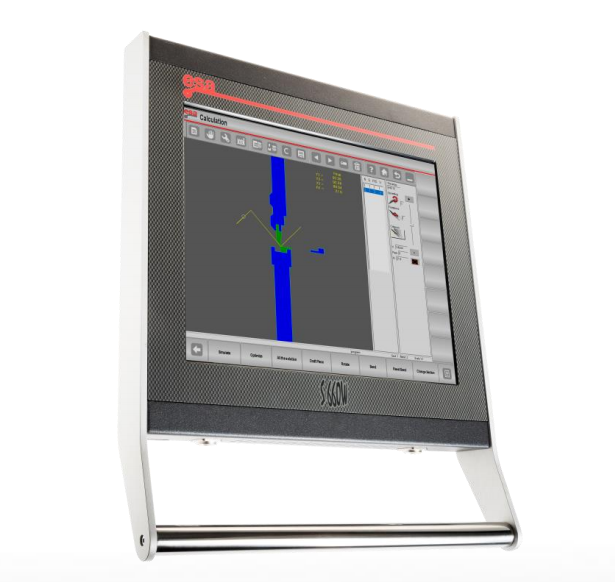

The most powerful CNC control with Panel PC. Graphical 3D programming at the highest level with an extra large 19 '' multitouch control panel for optimal ease of use to get the most out of your machine.

General software functions

Graphical 2D programming of workpiece and tool

Presentation of the machine structure, the workpiece and the tools

Automatic calculation of the bending force limitation based on the max. Load capacity of the tools

Automatic calculation and optimization of the bending order

Management of 3D CAD / CAM images

Automatic calculation of the crowning

Automatic calculation of stock size

Automatic management of folded sheets

Automatic calculation of the bending radius curvature for large bending radii

Multi-tandem management for the combination of tandem or multi-tandem presses (max 4)

Programmable workpiece counter

Switch between mm / inch

Windows® user interface

Network connection / remote maintenance

Optional software features

Dynamic error compensation of the machine during the bending process by the CNC / drives (dynamic crowning)

Management of bending angle measurement and relative dynamic compensation during bending

Automatic determination of sheet thickness

Angle correction database to apply corrections to the angle, material or tool. Corrections are automatically loaded into the new programs

Interface for LED strips from Wila and Esautomotion

Mitutoyo goniometer interface for correcting the bending angle (cable included)

General features

Programmable axes and auxiliary functions Control of hydraulic axes with proportional or servo valves, DC and AC motors, brushless motors and converters, both traditional analog and fieldbus (Sercos, CAN, Mechatrolink, etc.)

Auxiliary axis management, connection to a robot with synchronization of robot / press programs, coupled presses (tandem)

Integration of a safety PLC (Pilz, Fiessler, Lazer Safe, MCS)

Modifiable PLC (IEC 61131-3) with function blocks

both in STL and "C"

Customizable alarm management

Hardware features CNC

24 VDC power supply, 50 W max.

VIA Eden® X1 1.06 GHz, 1 GB RAM

128 MB SSD (Flash Disk)

2x USB 2.0

1x Ethernet 10/100 MBit (2x optional)

2x RS-232

1x CANopen (2x optional)

Hardware features Panel PC

24 VDC power supply, 70 W max.

AMD GX-424CC 2.4 GHz, 4 GB RAM

64 GB SSD (MSATA)

19 '' TFT LCD display with 1280x1024 SXGA resolution, glare protection

Capacitive PCAP multitouch control panel

Ergonomic housing

2x USB 2.0 external, 2x USB 2.0 internal

2x Ethernet 10/100/1000 Mbps

2x RS-232

Program memory and tool memory

SSD with space for at least 1,000,000 programs and tools

Axes

4 CNC axes (6 optional)

Control of the hydraulic crowning or Wila inputs with single-ended incremental encoder (5 V TTL) or line driver (RS 422)

Max. Encoder input frequency 500 kHz

Inputs and outputs

32 opto-isolated digital inputs PNP 24 VDC

32 opto-isolated digital outputs 24 VDC,

0.7 A, short-circuit proof

4 analog inputs 12Bit (0-5V, 0-10V)

2 analog outputs 12Bit (0-10V)

Direct control for pressure valve and crowning valve (max 3 A)

Direct control of proportional valves for Y1 and Y2

with and without feedback (maximum 2.8 A)

I / O extension via ESAring interface with up to 512

digital inputs, 512 digital outputs, 8 analog inputs,

8 analog outputs (optional)

Offline Software

Free offline software for Windows®

Analogous to the programming software of the CNC control on the machine

Complete bending simulation