Fiber Laser Cutting Machine

Professional and Reliable Fiber Laser Cutting Machins

DURMAPRESS®, a top leading manufacturer in the CNC machines industry. We offer a range of different series including the BS-D Series Open Type Single table Fiber Laser Cutting Machine, BS-H Series Full Covered Fiber Laser Cutting Machine with exchange table, BS-E Series Full covered Tube & Sheet Fiber Laser Cutting Machine, BS-G Series Open Type Tube & Sheet Fiber Laser Cutting Machine, as well as the most advanced Robotic Fiber Laser Cutting Machine and Professional Tube Laser Cutting Machine.

Our sheet metal cutting machines are designed to meet your production needs with different budgets and requirements. In addition, our experienced team can also design custom laser cutting machines for your specific applications. Contact us today for an instant quote and discover the quality and precision of DURMAPRESS® Fiber Laser Cutting Machines.

BS-D Series Fiber Laser Cutting Machine

Desktop type fiber laser cutter, most popular solution.

The BS-D Series is our economical metal sheet fiber laser, specifically designed for high precision cutting applications and perfect for small to medium business. It has an open bed design with the option to add an full cover if required.

This machine is suitable for cutting thin sheet metals such as carbon steel, stainless steel, galvanised steel, aluminium etc.

- Model: BS-D (Economic)

- Laser Power: 1000 - 2000W

- Processing Area: 3*1.5(m)/4*1.5(m)/4*2(m)/6*1.5(m)

BS-D Pro Series Fiber Laser Cutting Machine

Much Higher speed with stronger bed design .

The BS-D Pro Series is a high production fiber laser cutter, offering you precision cutting with high acceleration and speed for the best finish over a range of materials and thicknesses.

It will offer small to medium businesses the ability to cut thin sheet metals such as carbon, stainless steel, galvanised steel, aluminium etc.

- Model: BS-G(High Speed)

- Laser Power: 2000 - 6000W

- Processing Area: 3*1.5(m)/4*1.5(m)/4*2(m)/6*1.5(m)

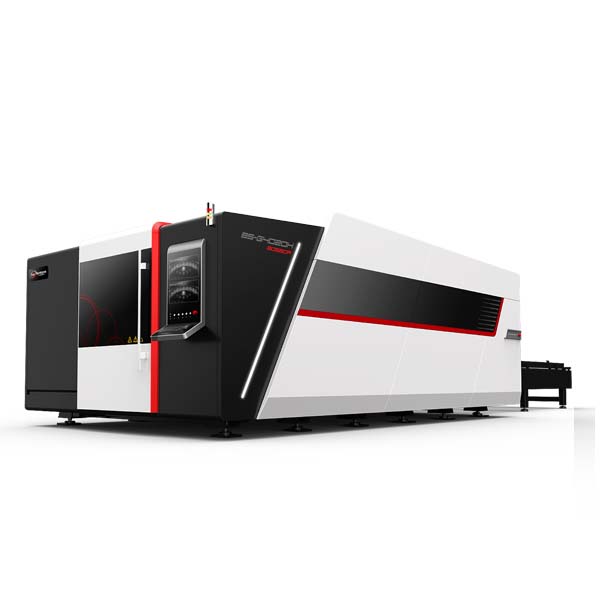

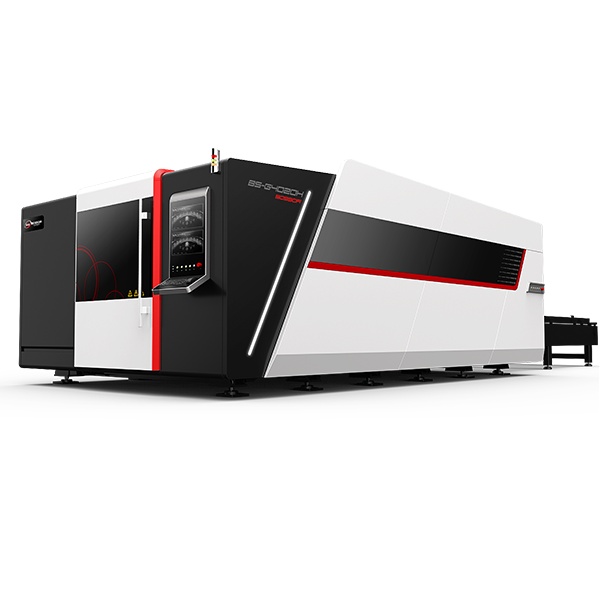

BS-H Series Closed Fiber Laser Cutting Machine

Full Covered Type Laser Cutter , Exchange Table improve working

The BS-H Series is our fully enclosed dual table industrial fiber laser cutter. It is designed with a range of features, like the dual interchangeable table system, making it ideal for high production cutting. With a CE certified glass enclosure, this machine offers safety when incorporated into factory layouts or educational environments.

This fiber laser cutter is suitable for cutting sheet metals such as carbon, stainless steel, galvanised steel, aluminium, brass etc.

- Model: BS-H(Full Clovered )

- Laser Power: 1000 - 8000W

- Processing Area: 3*1.5(m)/4*1.5(m)/4*2(m)/6*1.5(m)

BS-G Series Tube & Plate Fiber Laser Cutting Machine

The BS-G Series is our production open bed fiber laser with rotary cutting along with dual loading table. Designed for precision and high production cutting applications, this machine is useful for a multitude of applications

This metalworking laser is suitable for cutting sheet metals such as carbon, stainless steel, galvanised steel, aluminium and brass along with round, oval, square, rectangle, hex tube from 20-200mm diameter.

- Model: BS-E Series

- Laser Power: 1000 - 6000W

- Processing Area: 3*1.5(m)/4*1.5(m)/4*2(m)/6*1.5(m)

- Diameter : 180-320mm

- Length : 3-6 meters

BS-E Series Closed Tube & Plate Fiber Laser Cutter

The BS-E Series is our fully enclosed production fiber laser with rotary cutting. Designed for precision and longevity it has been made for high production applications.

This metalworking laser is suitable for cutting sheet metals such as carbon, stainless steel, galvanised steel, aluminium and brass along with round, oval, square, rectangle, hex tube from 20-200mm diameter.

- Model: BS-E Series

- Laser Power: 2000 - 6000W

- Processing Area: 3*1.5(m)/4*1.5(m)/4*2(m)/6*1.5(m)

- Diameter : 180-320mm

- Length : 3-6 meters

BS-T Series Tube Fiber Laser Cutter

The HS-T Series is our production open bed fiber laser with rotary cutting. Designed for precision and high production cutting applications, this machine is useful for a multitude of applications.

This metalworking laser is suitable for cutting round, oval, square, rectangle, hex tube from 20-200mm diameter.

- Model: BS-T Series

- Laser Power: 1000 - 6000W

- Diameter : 180-320mm

- Length : 3-6 meters

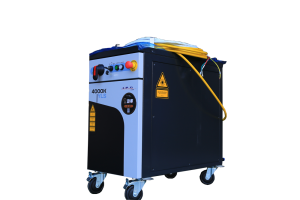

MasterPlus 6Kw-15Kw Fiber Laser

Includes Following Features And Configuration

Flexiable

Reliable

Friendly Using

High Effiency

Fiber Laser Cutting Machine Video

DURMAPRESS®Different Series Fiber Laser Cutting Machine Working Video Testing Before Delivery, Welcome Contact Us!

Why Durmapress ® Laser Cutter ?

Durmapress High Quality

with automation modules to create a complete

system for the whole working process.

Customized solutions at a reasonable price,

from basic to high end machine.

Experience

installed machines. An expert R&D team committed to research the most competitive

technology for our customers.

After-Sales Service

spare parts to guarantee full performance and

prolonged durability. Wide range of

consultation services on machine operation

, programming and maintenance.

5 Years Warranty

spare parts to guarantee full performance and

prolonged durability. Long-life service for technical support

More Varied Solutions for Cutting

responsibility are characteristics of modern

companies and add to competitiveness.

Comprehensive range of basic tools in stock

and modified solutions according to

customer needs.

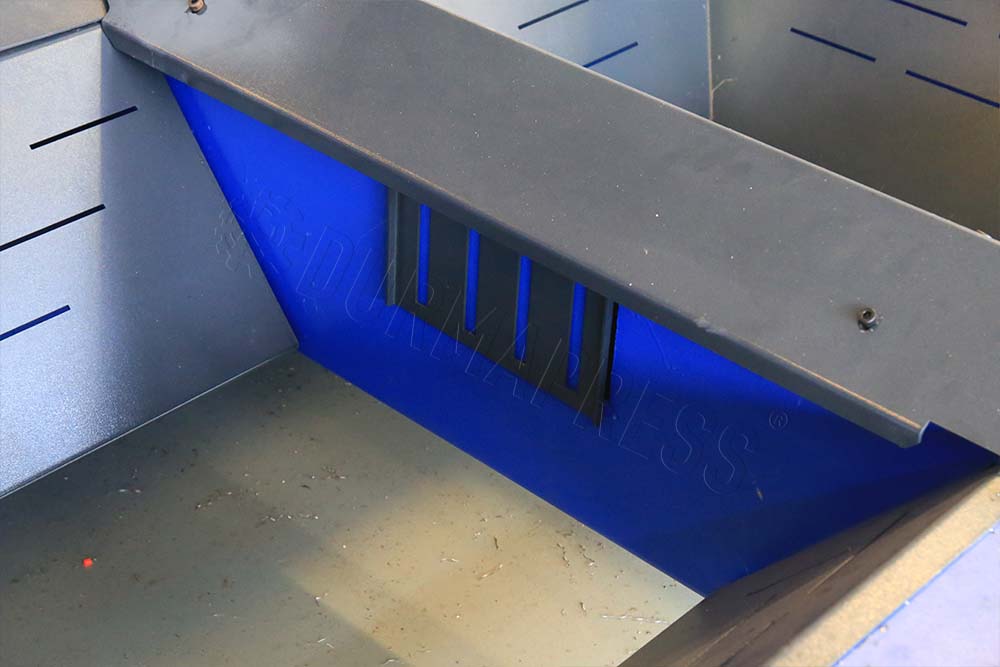

Quality Stronger Machine Bed Frame

Durmapress ® Bed frames undergo annealing at over 600⁰ to relieve stress. and they are built to no deformation with heavy working for many years.

Advantage:

- Very stiff and stable base frame

- Deformation simulation made by CAE

- Eight(8) zone & ducted exhaust system

- Dual synchronized twin servo motor drive system

- Helical rack & slant pinion drive system enables very smooth Movements

Fully Annealed Frame

Durmapress Innovative gravity-wrap ultra-high-power full-hollow bed with no square connection in the middle, no shielding in the cutting area, and the bed is not subject to high-temperature roasting, no burn out, more durable.

Graphite Anti-Burn Technology

The area in the entire machine tool where the laser can shoot at isall covered and protected by 20mm thick graphite anti-bruning To insuring the machine bed and working table not be out of shape and burned-out.

Perfect Multitasking-Laser Generator

Laser-cutting thick materials with new power. Focus management creates geometries that were impossible until now with smooth, well-defined edges. The use of water makes nesting more compact. The use of air guarantees the lowest cost per part ever.

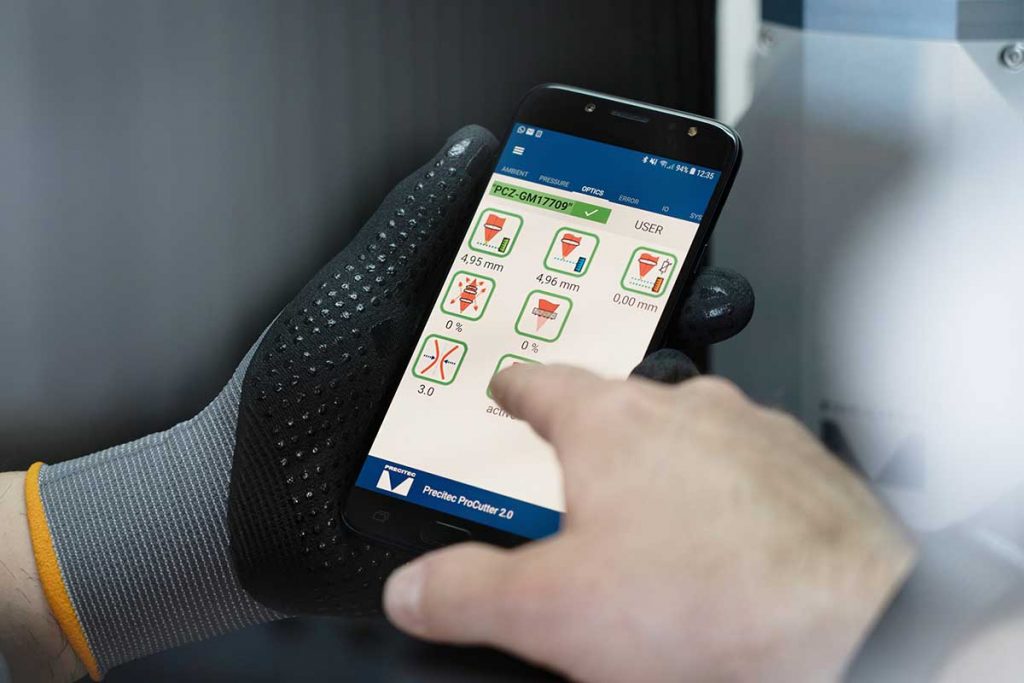

Precitec ®Laser Cutting Head

The powerful ProCutter 2.0 can be operated with up to 40 kW laser power and offers its usual extensive functionality and flexibility. It ensures high dynamics with thin material thicknesses and best quality with thick materials. Especially for flatbed, tube cutting, and laser blanking systems, the potential of the cutting head is optimally converted into productivity.

- Highest cutting speeds

- Excellent quality of the cut edges

- Intelligent sensor technology for stable processes

Laser Cutting In The Medium Power Range

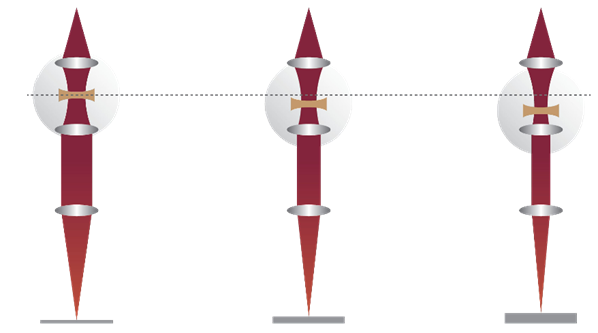

The ProCutter Zoom 2.0 depend on thickness, it is available to control the beam size and make a exact angle of incidence. widen cutting width, blow out the material melting easily.

Cutting Head Procutter Zoom 2.0

1000-times reliability in use: the ProCutter 2.0 impresses worldwide with its high performance and automation. Its reliability and load capacity in flatbed and tube cutting systems has been perfected - up to a maximum laser power of 40 kW.

Knowledge For Fiber Laser Cutting Machine

What is Fiber Laser Cutting Machine ?

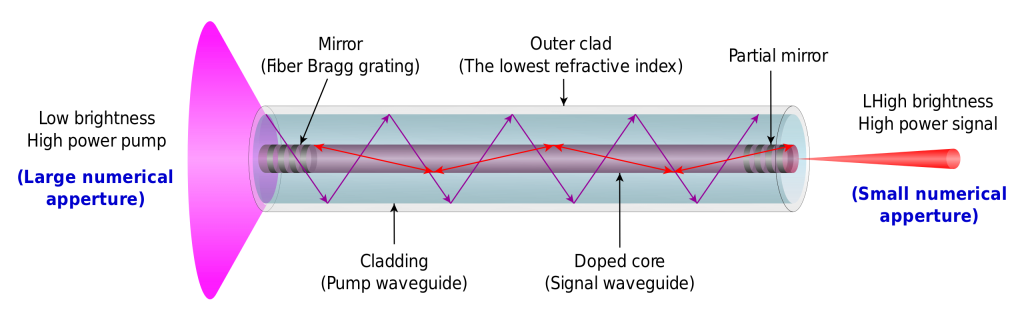

-Fiber laser cutting machine is a laser cutting machine that uses a fiber laser generator as the light source

What is Fiber Laser Generator ?

-Fiber laser is a new type of fiber laser output high energy density laser beam which new developped in the international, and gathered on the surface of the workpiece, so that the workpiece by the ultra-fine focus spot irradiation area instantaneous melting and vaporization, through the CNC Controller system to move the spot irradiation position and achieve automatic cutting, fast speed, high precision.

The Advantages of Fiber Laser Cutting Machine ?

-Fiber laser cutting machine which can do both flat cutting and bevel cutting processing, and the edge is neat and smooth, suitable for metal sheet plate and other high-precision cutting processing, at the same time plus the Robort Arm can be three-dimensional cutting instead of the original imported five-axis laser. The laser cutting machine is more space-saving and gas-consuming than the ordinary CO2 Laser Cutting Machine, with high photoelectric conversion rate, which is a new product of energy-saving and environmental protection, and one of the world's leading technology products.

Material Suitable Cutting By Fiber Laser Cutting Machine ?

-Cutting of Stainless Steel, Carbon Steel, Alloy Steel, Silicon Steel, Spring Steel, Aluminium, Aluminium Alloy, Galvanised Sheet, Aluminised Zinc Sheet, Pickled Sheet, Copper, Silver, Gold, Titanium and other metal sheets and tubes.

How to Confirm Fiber Laser Cutting Machine Model ?

-There is some Basic characteristics to calculate the Laser Power , then detemine the Fiber Laser Cutting Machine model .Before You buy the Fiber Laser Cutting Machine , you need some Sheet Metal details at least .

- Material ( Such as Carbon Steel , Stainless Steel , Aluminum and ect )

- Thickness ( For example 4mm , 6mm and more )

- Working Size ( For example 3000*1500mm and ect )

- Do you prefer Open Type or Full Covered ?

After these characteristics have been determined, We can calculate the laser power required for the bending operation.

Otherwise , How to Choose A good machines , Check Below !

How to Choose a good Fiber Laser Cutting Machine?

1.Cutting surface roughness (Rz)

2.Slag size of the cutting edge

3. Cut edge verticality and slope (u)

4. Cut edge rounding dimension (r)

5. Streak back drag (n)

6. Flatness ( F )

How to Choose a good Fiber Laser Cutting Machine?

1.Cutting surface roughness (Rz)

2.Slag size of the cutting edge

3. Cut edge verticality and slope (u)

4. Cut edge rounding dimension (r)

5. Streak back drag (n)

6. Flatness ( F )

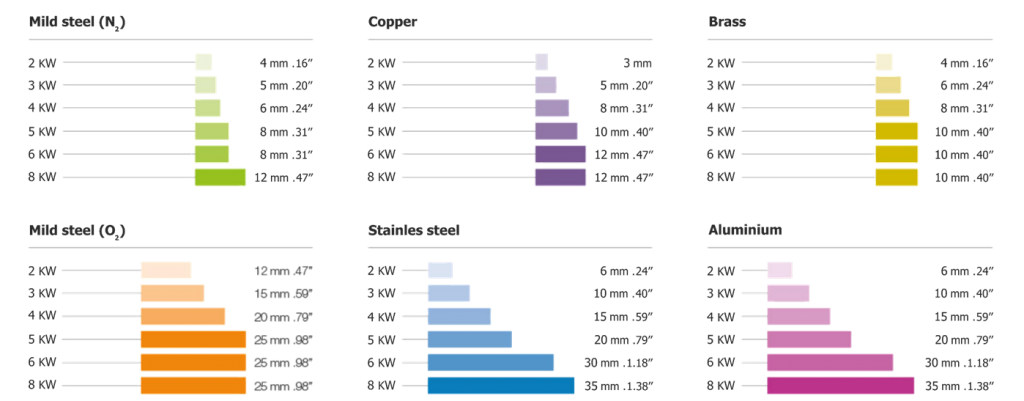

Thickness Range Cutting by Fiber Laser Cutting Machine?

Fiber laser cutting machines have different cutting capabilities depending on their power, but almost all fiber laser machines can cut a sheet of metal that is up to 13mm thick. Higher powered fiber laser machines with 12kW to 20KW of power can cut mild steel up to 60mm and stainless steel and aluminium up to 30mm.

What Are The Applications Of Fiber Laser Cutting Machines?

A fiber laser cutting machine is incredibly useful in the manufacturing and infrastructure industries. Here are the top six applications of fiber laser cutting machines:

The Automotive Industry – A fiber laser cutting machine processes many parts of a car, including doors, brakes and exhaust pipes.

The Kitchenware Industry – Many of the appliances found in kitchens are made of thin pieces of stainless steel which have been processed by a fiber laser cutter.

Home Appliance Manufacturing – Fiber laser cutters are being incorporated more in this industry to improve the quality of appliances and optimise their appearance.

Fitness Machine Manufacturing – Even the equipment at your local gym has been processed in part by a fiber laser cutter.

Lighting Manufacturing – Most mainstream outdoor lamps have pipes which have been shaped with the help of this machinery.

Decor & Metal Art Manufacturing – Fiber laser cutters can be used with computer numerical control to create graphic designs and patterns in sheets of metal. This means custom pieces for decoration and metal signs can be crafted.

Just by looking around your home, the applications of fiber laser cutting machines instantly stand out. The persistent demand for these fiber laser machines is the reason why fiber laser cutting technology has advanced so quickly.

Many more essential things like transportation machinery and medical equipment could not be created efficiently and at scale without fiber laser cutting.

Fiber Laser Cutting Machine Cutting Advantages :

1, High Cutting Accuracy: Laser Cutting Machine positioning accuracy of 0.05mm, repeat positioning accuracy of 0.03mm.

2, Laser cutting machine slit narrow: Laser Beam focused into a very small spot, so that the focal point at a very high power density, the material is quickly heated to the degree of vaporization, evaporation to form a hole. With the relative linear movement of the beam and the material, so that the hole continuously formed a very narrow width of the slit, the width of the incision is generally 0.10-0.20mm.

3, Laser Cutting Machine Cutting Surface Smooth: Cutting surface without burr, the surface roughness of the kerf is generally controlled within Ra6.5.

4, Laser Cutting Machine Speed: Cutting Speed up to 10m / min maximum positioning speed of up to 30m / min than the speed of wire cutting much faster.

5, Laser Cutting Machine Cutting Quality: No contact cutting, cutting edge by the heat is very small, basically no thermal deformation of the workpiece, completely avoid the collapse of the edge formed when the material punching and shearing, cutting seam generally does not require secondary processing.

6, No Damage to the Workpiece: the laser cutting head will not be in contact with the surface of the material, to ensure that no scratch workpiece.

7, Not affected by the shape of the workpiece: laser processing flexibility, you can process any graphics, you can cut the pipe and other special profiles.

8, Saving Investment in Moulds: Laser Processing does not require moulds, no mould consumption, no need to repair moulds, saving time to replace moulds, thus saving processing costs and reducing production costs, especially suitable for processing of large products.

9、Saving Materials: With Computer Programming, different shapes of products can be cut, maximising the utilisation of materials.

10、Improve the Speed of sample leaving the factory: after the formation of product drawings, laser processing can be carried out immediately, and the new product can be obtained in kind in the shortest possible time.

11、Safety and Environmental Protection: Laser Processing waste less, low noise, clean, safe, no pollution, greatly improve the working environment.

Learn Fiber Laser Cutter Quality Control

Write us today

Write us today and our experts are ready to help. You can contact us by the contact form below or write us email or make a phone call!