Laser Cleaning Machine

General Features

Laser technology distributes thousands of focused laser pulses per second onto contamination layers, which makes it an ideal way of blasting them away. That said, not all layers are made of the same components. Rust and corrosion are different from paints and oils. Using lasers to weld is not the same as using them to clean. This is why we provide different laser cleaning solutions that can be tailored to your organization’s specific needs.

At Bossor Laser, we make our own laser systems, specifically designed for cleaning. We offer products with a range between 100 and 2,000 watts, and all of them provide unmatched results, with zero greenhouse emissions, no waste, and are fully safe for your employees.

The Advantage of Laser Cleaning

- It’s a non-contact, non-abrasive process. Home remedies are messy and unhealthy. Scrubbing off rusted surfaces exposes you to impurities which could lead to respiratory complications. Laser cleaning, on the other hand, relies on the laser beam to ablate the surface. There is no physical contact between you and the rust.

- No use of chemicals. Rust remover chemicals can get the job done, but the health implications on their use outweigh their benefit. Such chemicals are not only harsh and abrasive but also emit intense fumes. You will need to wear protective gear such as a respirator, goggles and rubber gloves before using them. However, laser cleaning does not rely on any chemical application. It is the better choice as it does not put your health at risk.

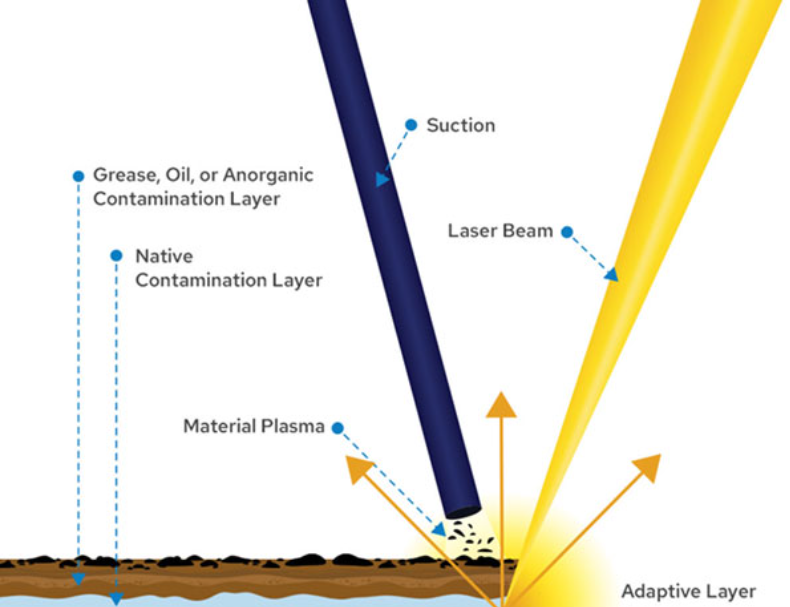

- No secondary waste is produced. Scrubbing off rust from surfaces only disintegrates the rusty particles from the substrate, leaving you with a toxic lump of rust dust at the end of the process. Electrolysis leaves the rust particles floating in the water, which you later have to dispose of. In comparison, laser cleaning is a cleaner process as the rust particles are either vaporized or turned into plasma, leaving no evidence of waste.

- High precision. The focused laser beams have an extremely precise focal edge, allowing you to ablate rust from tough spots that would otherwise be harder to clean with other apparatus. Such include the rust that develops around bolts and rails. Additionally, the high precision allows you to focus the laser beam repeatedly over a specific area to achieve the required depth and result.

- It’s effective on all surfaces. Unlike other rust removal procedures, laser cleaning works on all surfaces that are prone to rusting, including stones, concrete, iron, aluminum (bauxite) or copper.

- It does not degrade the substrate. Scrubbing rusted surfaces significantly degrades the substrate due to friction. Rust removing chemicals, on the other hand, are harsh and corrosive, causing wear and tear that could spoil delicate metals or even weaken their robustness. Laser cleaning in comparison ablates the surface while leaving the substrate untouched.

- It is a long-term solution. A laser cleaning machine will serve you longer than any scrubber or rust removing chemical will. The laser does not suffer any wear or tear, and thus can be used and reused over its lifetime.

Why Choose Laser Cleaning Machine

Whether you need a mobile cleaning solution that is capable of flexible projects or you’re looking to automate a regular cleaning process, we can create the perfect laser solution for you. If you’re not sure which delivery method is ideal for your project, don’t worry! Our dedicated team of laser experts will walk you through the process to ensure you have the right laser setup for the job, every time.

Choose Durmapress Laser Cleaning Machine Model

Laser Cleaning Technology

Laser technology works by sending nanosecond-length pulses of laser light towards a surface. When it interacts with contaminants that absorb laser light, the contaminants or coating particles will either turn into a gas or the pressure of the interaction will cause particles to free from the surface.

With the right laser settings and equipment, laser cleaning is unmatched in its ability to clean all the way to the bare metal of your product. Adapt Laser specializes in the know-how and application of laser cleaning solutions to put together the formula for your specific situation. Once we identify the combination of settings and equipment, the process can be matched across other setups – working very efficiently without affecting the integrity of the surface you are cleaning.

Lower Power Handheld Cleaning Lasers-100W

Our low-power cleaning lasers are an effective cleaning solution that’s perfect for small areas where precision is key. They’re also gentle enough for cleaning historic artifacts or precious family heirlooms without damaging them.

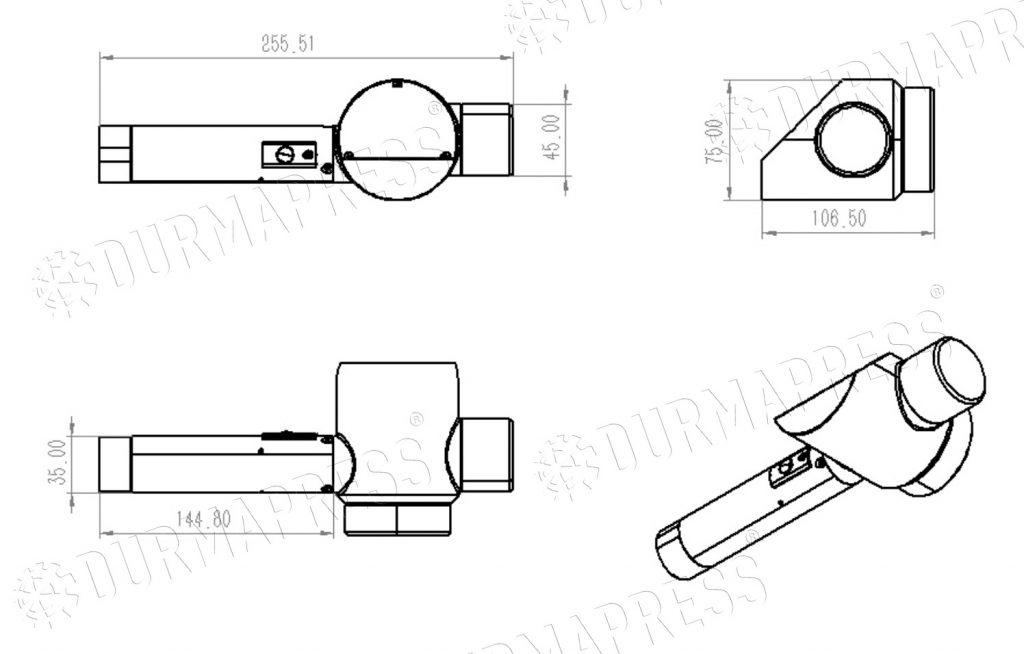

• Small size and light weight, convenient for users to hold and use for a long time.

• Two-dimensional scanning, you can choose a straight line or rectangular filling method, the line width can be adjusted.

• The current maximum power can use 200W, can be equipped with YDFLP-CL-100-1-A, YDFLP-CL-200-12-A.

Mid Power Handheld Cleaning Lasers-200W 300W

Our mid-power lasers are ideal for cleaning applications involving larger surfaces. This includes, but is not limited to composite part molds, aircraft coating removal, and pre-welding treatments.

High Power Handheld Cleaning Lasers-1000W

Our high-powered lasers are some of the most powerful cleaning solutions on the market. These lasers are ideal for industrial applications as well as for radiological decontamination.

WHAT WORKS – AND WHAT DOESN’T?

Laser cleaning is technology that is more effective, safer and superior to traditional methods of cleaning; however, laser cleaning is not infallible. While lasers are ideal to use on most surfaces, there are limitations.

For example, if you need to remove rust, our laser units will do so at a much faster rate than if you had to remove very thick coatings over a large area. By the same token, flat surfaces will experience better results than if you have to clean surfaces with limited line of sight.

This doesn’t mean that laser technology only works on simple tasks. We do provide techniques for complex, 3D surfaces, but removing layers with a thickness of more than 0.5mm tends to not be cost effective. If you have questions about whether laser cleaning is a viable solution for your business, our team is always ready to assist you.

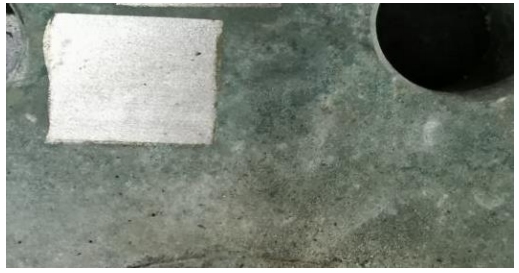

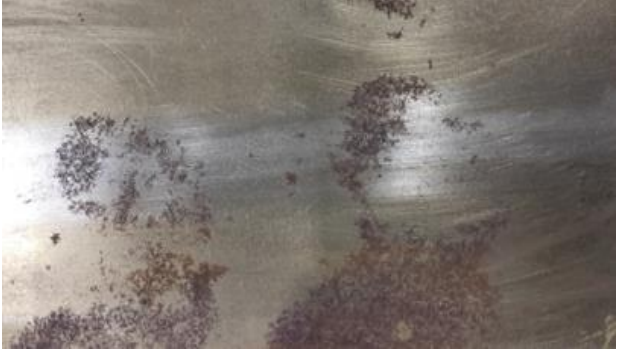

Cleaning sample display

Rail derusting

Oxide and pollutant cleaning on the surface of steel pipe

Copper alloy surface patina cleaning

Laser descaling application

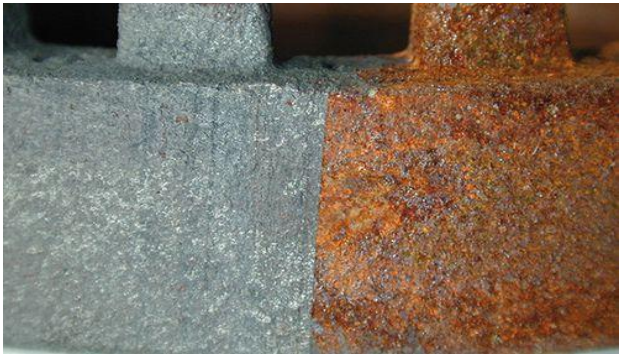

Thick rust layer

Thin rust layer

The thick rust layer is difficult to clean, and the cleaning energy density required is high. Single-mode lasers can easily achieve high energy density at the focal point, so the

It is more suitable to use a single-mode laser when cleaning thick rust, and the cleaning efficiency is high.

The thin rust layer is less difficult to clean, and the cleaning energy density required is low. The multimode laser has low energy density at the focal point, and the spot distribution is relatively

Uniform, not easy to damage the substrate. Therefore, it is more appropriate to use a multi-mode laser when cleaning thin rust layers.

| Technical Parameters | ||

|---|---|---|

| DURMAPRESS Supply Laser Cleaning Machine 100W/200W/300W/1000W | ||

| Model | CL100/CL200/CL300/CL1000W | |

| Cleaning width | 1-20mm | |

| Scanning speed | 13000mm/s | |

| Cleaning length | 1-100mm | |

| Laser frequency | 1-2000KHz | |

| Laser power | 200W/300W/500W/1 000W/1500W/2000W | |

| Spiral Series | 1-100mm | |

Product Video

Write us today

Write us today and our experts are ready to help. You can contact us by the contact form below or write us email or make a phone call!