Hydraulic Ironworker

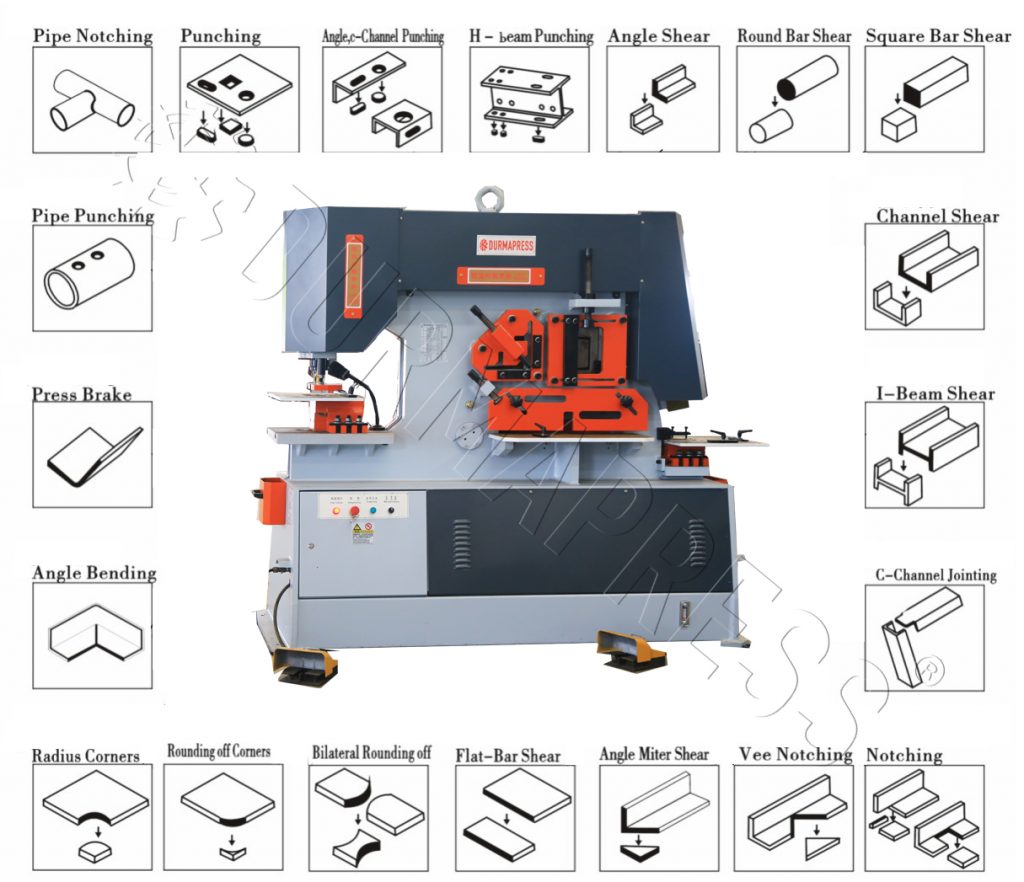

DURMAPRESS Q35Y Series, is capable of operating when high volume of work is required. 5 stations enable to make the production more efficient and it can be operated by one foot pedal. It is capable of punching, flat shearing, angle shearing, bar shearing and notching that makes it the perfect fit to serve you for your metalworking needs.

Ironworker Machine We Help You Produce In China

DURMAPRESS® China Top Leading Professional Manufacture to make the Ironworker Machines ,lronworker Machines are divided into hydraulic lronworker Machines and mechanical lronworker Machines, ofwhich hydraulic type is the most widely used. The Hydraulic lronworker Machine is generally suitable forprocessing small workpieces, and can work in multiple stations at the same time. The left foot switch individually controls the punching station, and the right foot switch controls the operation of other jobs at the same time.Durmapress Brand Rich Experience can also design different Types of Press Brake Toolings for End-user Customers Jobs.Please Contact us for instant Quote!

Q35Y Series Hydraulic Ironworker

Multi-functions Machine

- Model: Q35Y Series

- Function: Punching , Cutting , Bending , Notching

- Capabilities: 16Ton-160Ton

Q67Y Hydraulic Punching Machine

Hydraulic Punching Machine

- Model: WC67K

- Function: Punching , Bending

- Capabilities: 16Ton-160Ton

Knowledge For Press Brake

What is Ironworker ?

The ironworker which combined punching and shearing machine is a machine tool that integrates various functions such as metal notching, punching, plate shearing and bending. It has the advantages of easy operation, low energy consumption and low maintenance cost. It is a modern manufacturing industry (such as: Metallurgy, bridge, communication, electric power, military and other industries) metal processing preferred equipment.

Functions :

- Punching: Including round holes, square holes, waist slot holes and other special-shaped holes, and undertake the processing and production of molds (Using 9CrSi material, after heat treatment, the hardness is higher), widely used in railway bridge construction, ship accessories, steel Structure factory and other industries.

- Shearing board: One stroke can be cut to 8x2200 or 12x330 (National Standard), and the size can be modified according to the actual needs of users (including enlargement)

- Shearing section steel: including channel steel, angle steel I-beam, round steel square steel, channel steel, etc. are readily available, the shearing port is flat, and the operation is simple

- Cut Corners: According to the actual needs of users, it includes: notches, corners, openings, etc.

- Angle Steel Channel Cutting Station: Cutting station, through the replacement of molds, angle steel, angle iron, channel steel and other materials can be cut.

- Shearing Station: Angle steel, angle iron, channel steel, square steel, round steel, flat steel. The shearing of various profiles can be achieved by changing the mold.

Ironworker Machine Application Industry

1. Steel structure processing

2. Elevator car and parts processing

3. Trailer---spare tire parts, trailer hinges, hooks, inserts, tile panels

4. Construction machinery industry---processing on belt conveyor and mixing station

5. Agriculture and animal husbandry machinery industry---threshing frame body, trailer body parts processing

6. Food industry machinery - slaughtering equipment frame and parts processing

7. High and low voltage iron tower parts processing

8. Wind power equipment --- parts processing on stairs and pedals on wind power towers

9. Machining --- processing of building embedded parts/conveyor brackets and other components for connection

10. Grain machinery---grain and oil equipment, starch equipment bracket, shell, small parts processing

11. Processing of railway wagons/automobiles and crane parts

12. Cutting, punching and bending of channel steel, square steel, round steel, H steel, I-beam and other steels

Ironworker Machine Application Industry

1. Steel structure processing

2. Elevator car and parts processing

3. Trailer---spare tire parts, trailer hinges, hooks, inserts, tile panels

4. Construction machinery industry---processing on belt conveyor and mixing station

5. Agriculture and animal husbandry machinery industry---threshing frame body, trailer body parts processing

6. Food industry machinery - slaughtering equipment frame and parts processing

7. High and low voltage iron tower parts processing

8. Wind power equipment --- parts processing on stairs and pedals on wind power towers

9. Machining --- processing of building embedded parts/conveyor brackets and other components for connection

10. Grain machinery---grain and oil equipment, starch equipment bracket, shell, small parts processing

11. Processing of railway wagons/automobiles and crane parts

12. Cutting, punching and bending of channel steel, square steel, round steel, H steel, I-beam and other steels

Operation Tips

- Check the power supply, the voltage is stable, there is no phase loss, and the leakage protector and air switch are in good condition.

- Wiring, open the connection cabinet of the combined punching and shearing machine, connect the wires, and close the cabinet door.

- After the power is turned on, step on the foot switch, the machine does not move, exchange the power cords, and check whether the emergency stop switch is turned on.

- Connect the foot pedal switch.

- When working, pay attention to turn off the power every time you change the mold.

- After finishing the work, turn off the switch, turn off the main power switch, remove the power cord, and clean the debris.

Maintenance Tips

- Operate in strict accordance with the operating Manual Book.

- Add lubricating oil according to the requirements of the lubricating chart at regular intervals, fixed points and quantitatively before each startup. The oil should be clean and free of precipitation.

- The ironworker machine must be kept clean frequently, and the unpainted part must be kept with anti-rust grease.

- The lubricating oil in the motor bearing should be replaced and filled regularly, and the electrical parts should be checked regularly to see if they are working normally, safely and reliably.

- Always check whether the V-belt, handle, knob and button of the ironworker machine are damaged. If the wear is serious, it should be replaced in time and reported for spare parts.

- Regularly check and repair switches, insurances and handles to ensure reliable operation.

- 10 minutes before leaving get off work every day, lubricate the machine tool and scrub and clean the machine tool.

Write us today

Write us today and our experts are ready to help. You can contact us by the contact form below or write us email or make a phone call!