Guillotine Shearing Machine

Hydraulic Guillotine Shearing Machine

General Features

- The entire EU streamlined design, heat treatment frame, high rigidity workbench, optional mechanical

- compensation device for precise bending.

- Hydraulic synchronization control and Estun NC programmable logic controller ensure precise repeatability

- and ease of use.

- The integrated hydraulic system (Bosch Rexroth, Germany) can quickly and automatically switch to a slow bend.

- The X-axis and Y-axis are programmed by the NC E21 system to achieve accurate positioning of the inverter.

- Advanced variable frequency hydraulic control technology, with more stable, and more reliable operation.

- The optimal parameter ratio and optimal core configuration ensure stable performance and convenient operation.

- WC67K series press brake equipped with standard single-axis backgauge system (X-axis) and single-axis bending

- angle system (Y-axis), you can choose to add V-axis compensation function, and select the appropriate mold to

- easily bend the workpiece with complex shapes.

E21S NC Controller From ESTUN

Controller Data

- High-definition LCD display with Chinese and English language options. Programming parameters can be displayed on one page, making programming faster and more convenient.

- Backgauge: Intelligent positioning, manual adjustment can also be performed as needed, and mechanical manual positioning device is eliminated.

- Shearing stroke: Built-in shearing time relay, easy operation and cost saving.

- Cutting angle: built-in cutting angle adjustment function, eliminating the angle indicator and buttons.

- Knife edge clearance: encoder feedback, timely display of knife edge clearance, easy and convenient operation.

- With one-key parameter backup and recovery function, parameters can be restored at any time as needed, reducing maintenance costs.

- All keys on the panel are micro switches, which have passed strict tests such as EMC, high and low temperature, and vibration to ensure product stability and service life.

Guillotine Shearing Machine Working Video

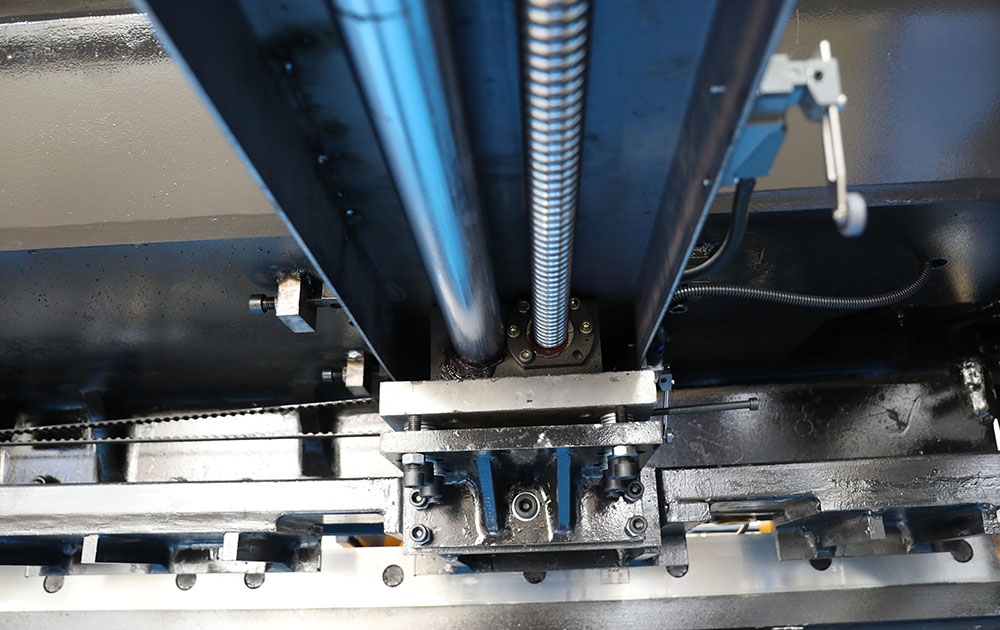

- The blade gap is adjusted by the motor, scaled display, easy to operate, to meet the cutting needs of different plate thicknesses and materials.

- The cutting stroke is controlled by the time relay. The cutting length is adjusted so that the blade does not need to complete the entire cycle, which saves working time, increases the number of strokes, and improves production efficiency.

- The number of cuts is controlled by a counter. The counter has the function of setting and memory, and has the functions of forward, backward and fine adjustment.

- The light line shadow alignment device is convenient for drawing and cutting.

- Hydraulic electric control adjusts the cutting angle. The shear angle can be adjusted within the specified range. When cutting thin plates, the cutting quality can be further improved, and when cutting thick plates, the thickness of the cut plate can be increased. When cutting narrow strips, the advantage of the adjustable shearing angle is more prominent: a smaller shearing angle can reduce the distortion of the strips

Main Components

Hydraulic Guillotine Shears

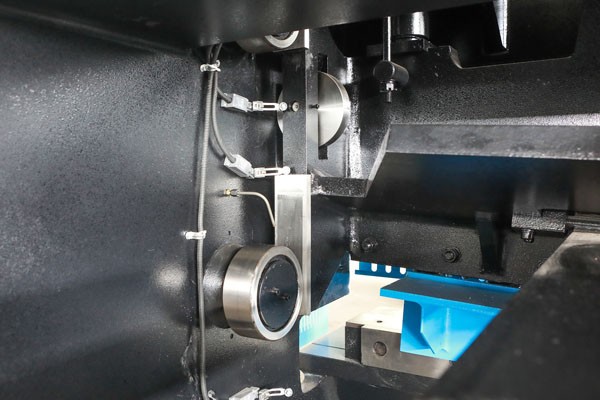

After shearing, the shearing machine should be able to ensure the straightness and parallelism of the shearing surface of the sheared sheet, and minimize the distortion of the sheet to obtain high-quality workpieces. The upper blade of the shearing machine is fixed on the knife holder, and the lower blade is fixed on the workbench. A material holding ball is installed on the workbench to prevent the sheet from being scratched when sliding on it. The back gauge is used for positioning the plate, and the position is adjusted by the motor. The pressing cylinder is used to compress the sheet material to prevent the sheet material from moving during shearing. The guardrail is a safety device to prevent industrial accidents.

Hydraulic system is safe and reliable

◆The liquid system manifold is equipped with a direct-acting safety relief valve to ensure accurate pressure adjustment.

◆In order to protect the safety of the oil pump, a pipe check valve is specially set at the pump head to avoid the impact of oil pressure on the pump body.

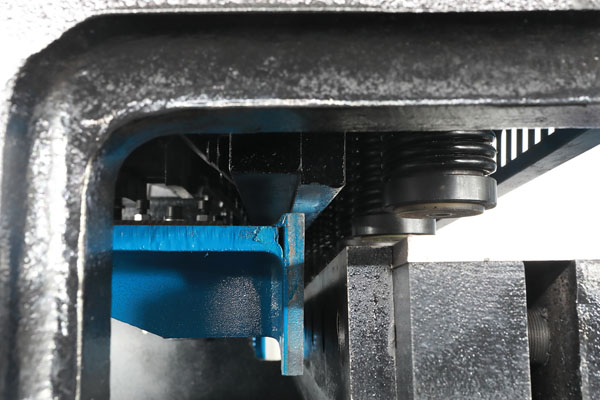

Blade

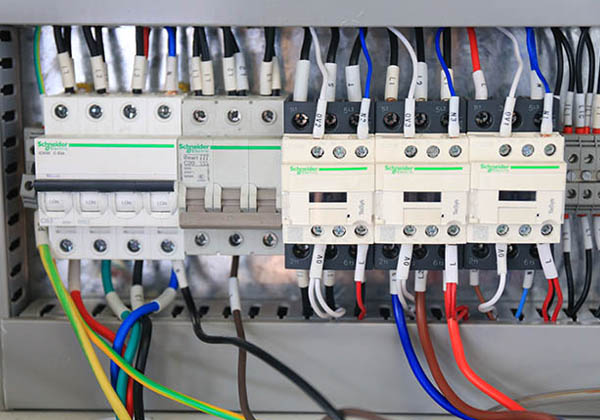

Centralized and reliable electrical control

◆The power facilities are all set in the fuselage, which can be controlled and realized by operating the buttons on the control panel.

◆Equipped with a foot switch, through which the cutting action can be directly operated, which is convenient and quick.

◆The main electrical components are Schneider products.

◆The safety fence can protect the safety of the operator and can clearly see the cutting situation, which is safe and convenient.

◆Use a circuit breaker to protect the short circuit of the control circuit.

◆The overload and short circuit of the motor are protected by an air switch.

◆The operation panel and foot switch are equipped with emergency stop switch buttons, which can stop the machine in time when the operation is wrong.

OTHER COMPONENTS

-

- Rexroth Valve

-

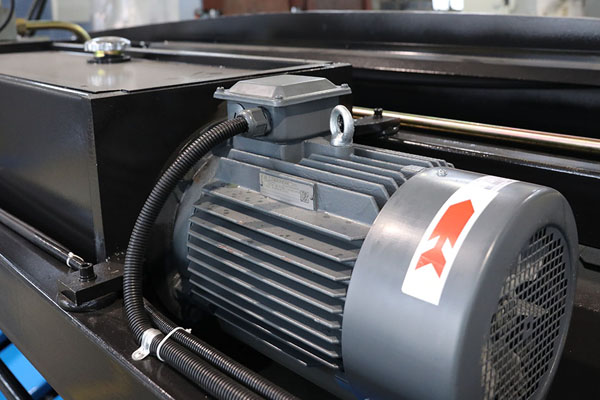

- Siemen Motor

-

- Ball Screw

-

- Electrical Box

-

- Auto Blade Clearence

-

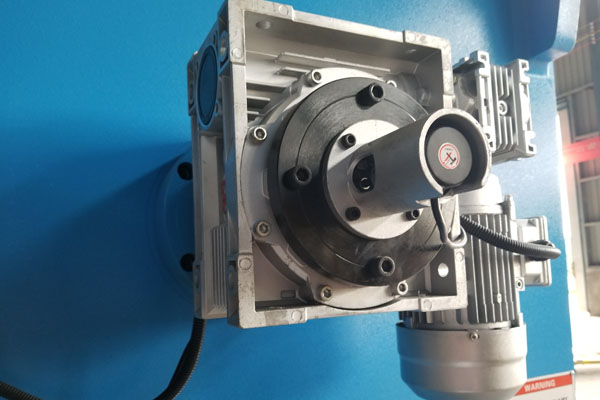

- Back Gauge motor

-

- Throat

-

- Oil Cylinder

-

- Stroke Slider

Technical Data

QC11Y Hydraulic Shearing Machine with E21s NC Controller

| Seri-al NO. | Name | Unit | 6x3200 | 6x4000 | 8x2500 | 8x3200 | 8x4000 | 8x6000 | 12x2500 | 12x3200 | 12x4000 | 12x6000 | 16x2500 | 16x3200 | 16x4000 | 16x6000 | 20x3200 | 20x6000 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Max. Cutting Thickness | mm | 6 | 6 | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 12 | 16 | 16 | 16 | 16 | 20 | 20 | ||||||||||||||||||

| 2 | Max.Cutting Length | mm | 3200 | 4000 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 | 3200 | 6000 | ||||||||||||||||||

| 3 | Strength of sheared plate | N/m㎡ | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | ||||||||||||||||||

| 4 | Cutting Angle | ° | 0.5-2.5 | 0.5-2.5 | 0.5-1.5 | 0.5-2.0 | 0.5-2.0 | 0.5-2.5 | 0.5-2.0 | 0.5-2.0 | 0.5-2.0 | 0.5-3.0 | 0.5-2.5 | 0.5-2.0 | 0.5-2.0 | 0.5-3.5 | 0.5-3.5 | 0.5-3.5 | ||||||||||||||||||

| 5 | Number of strokes | Hits/min | 6/12 | 6/12 | 6/12 | 6/12 | 6/12 | 5/8 | 6/10 | 6/10 | 6/10 | 6/10 | 8/12 | 6/10 | 8/12 | 4/8 | 5/8 | 5/8 | ||||||||||||||||||

| 6 | Length of Cutter Blade(A) | mm | 3300 | 4100 | 2600 | 3300 | 3300 | 6150 | 2600 | 3300 | 4100 | 6150 | 2600 | 3300 | 4500 | 6150 | 6150 | 6150 | ||||||||||||||||||

| 7 | Height of working table above the ground (C) | mm | 10-750 | 10-750 | 10-700 | 10-700 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | ||||||||||||||||||

| 8 | Backgauge Range of X Axis | mm | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-600 | 10-600 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | ||||||||||||||||||

| 9 | Main Motor | Type | Y132M-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | Y160M-4/(B35) | Y180M-4(B35) | Y180M-4/(B35) | Y180M-4/(B35) | Y180M-4/(B35) | Y180L-4/(B35) | Y180M-4/(B35) | Y200L-4/(B35) | Y180L-4/(B35) | Y180L-4/(B35) | Y180L-4/(B35) | Y225M-4/(B35) | ||||||||||||||||||

| Power | KW | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 18.5 | 18.5 | 18.5 | 18.5 | 22 | 22 | 30 | 22 | 22 | 30 | 45 | |||||||||||||||||||

| Rotate Speed | R/MIN | 1440 | 1440 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1440 | 1440 | 1440 | 1440 | |||||||||||||||||||

| 10 | Gear Pump | Type | NBZ3-G25F/CP1-25-P-10R | NBZ3-G25F/CP1-25-P-10R | NBZ3-G25F/CP1-25-P-10R | NBZ3-G25F/CP1-25-P-10R | NBZ3-G25F/CP1-25-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G63F/CP1-63-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G50F/CP1-50-P-10R | NBZ4-G50F/CP1-50-P-10R | NBZ4-G50F/CP1-50-P-10R | NBZ4-G50F/CP1-50-P-10R | NBZ5-G80F/CP2-80-P-10R | ||||||||||||||||||

| Norminal Flow | Ml/r | 25 | 25 | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 63 | 40 | 63 | 50 | 63 | 63 | 80 | |||||||||||||||||||

| Norminal Pressure | Mpa | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |||||||||||||||||||

| 11 | Back-gauge motor | Type | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | ||||||||||||||||||

| Power | KW | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | |||||||||||||||||||

| Rotate Speed | R/min | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | |||||||||||||||||||

| 12 | External Dimensions | Length | mm | 3700 | 4500 | 3000 | 3800 | 4500 | 6500 | 3100 | 3800 | 4500 | 6800 | 3100 | 3900 | 4600 | 6800 | 3900 | 6800 | |||||||||||||||||

| Width | 1800 | 1900 | 1800 | 1800 | 1800 | 2150 | 1900 | 1900 | 1900 | 2200 | 2000 | 2000 | 2000 | 2300 | 2000 | 2550 | ||||||||||||||||||||

| Height | 2000 | 2100 | 2100 | 2100 | 2100 | 2500 | 2300 | 2300 | 2300 | 2500 | 2400 | 2500 | 2400 | 2880 | 2500 | 2950 | ||||||||||||||||||||

| 13 | Power requirement | 380V (-15%,+15%) 50Hz ,3PH | ||||||||||||||||||||||||||||||||||