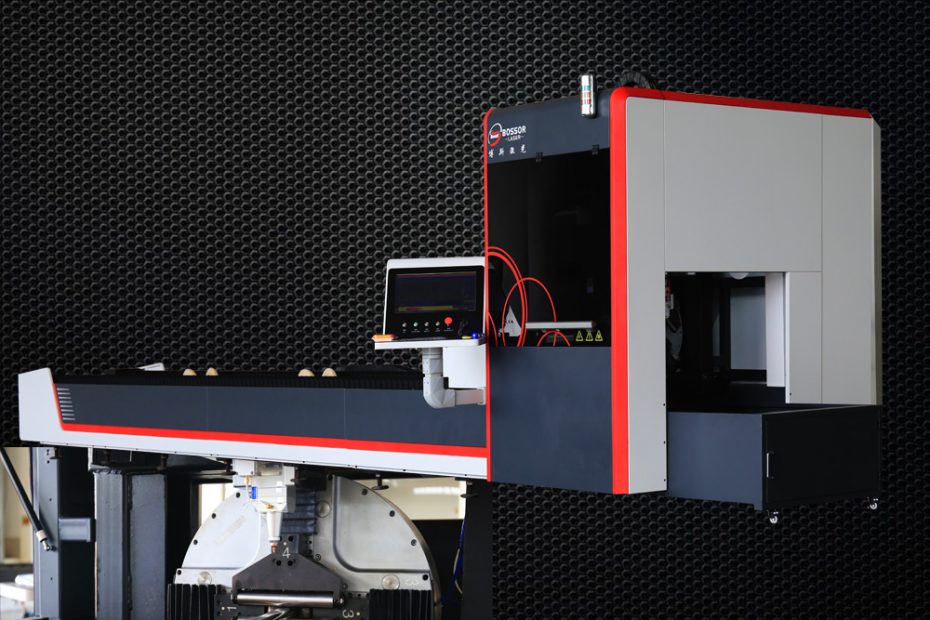

1, optical 2000w fiber laser machine for metal cutting operator before work, according to the equipment point check table

2. There is no obstruction to meticulous search, there is no doubt to promptly adopt missed punishment,

not the end of punishment, shall not be started privately.

2, search the cutting machine is not damaged, and clean up the stagnation, wipe the cutting machine,

discover the question of real-time punishment 2000w fiber laser machine for metal cutting.

3, check all the pneumatic system and pressure gauge is reliable, useful, no more than when the start.

4, search distribution box, power supply, grounding wire, guidance lamp, instrument, critical switch, button, whether normal, intact, vivid, reliable, useful.

5. Check whether the pneumatic parts of the machine are leaking, whether the pressure of the shrinking

atmosphere meets the requirements, and remove the water in the shrinking atmosphere before doing things every day.

6, search the drive parts of the machine tool combined with bolts, pins, shafts, keys,

limit switches, sensors and other signs of loose damage, and clean up the stagnation, remove wipe equipment, explore the question of real-time disposal.

7, search smooth and hydraulic system oil level and laser cooling system is normal, water level is normal,

there is a lack of liquid, lack of oil to real-time supplement.

The water level of the laser generator cooling water tank shall not be below the very low mark status.

Whether the water temperature is in the normal value, and ensure that the cooling water temperature is normal when the light.